Beyond Today, Shaping Tomorrow

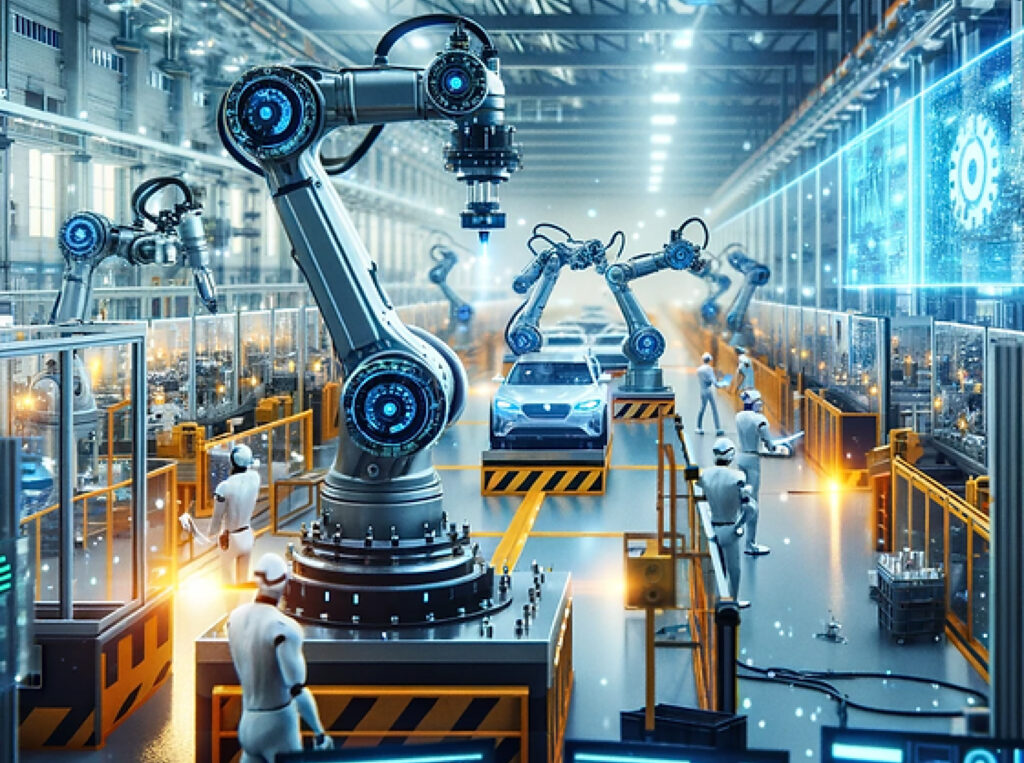

As we unravel the intricacies of DMark Lasers laser technologies, it becomes evident that the journey extends beyond the present. DMark Lasers doesn’t merely meet today’s demands; it pioneers the future of industrial processes. Every laser pulse echoes with innovation, shaping industries and leaving an indelible mark on the landscape of precision manufacturing.

The Continuous Pursuit of Innovation

DMark Lasers commitment to elegance in laser technology is an ongoing saga of innovation. With each technological advancement, the horizon of possibilities expands. From redefining welding precision to pushing the boundaries of laser cutting and marking, DMark Lasers innovation odyssey is a testament to an unwavering commitment to shaping a future where elegance and precision coalesce seamlessly.